How Toyota Went From Being Outproduced 350:1 to Revolutionizing Manufacturing

Toyota’s transformation from a struggling post-war manufacturer to the world’s largest automaker is more than just a business success story—it’s a masterclass in innovation through constraints. Let’s dive into how a company that was once outproduced 350:1 by GM became the blueprint for modern manufacturing.

The Post-War Reality

Following World War II, Japan was left in a precarious position. Steel and metals were scarce in a country already disadvantaged by lacking natural resources. Toyota, facing brutal financial constraints, had to close factories and lay off workers. The company was so resource-strapped that during the war, their model K truck was reduced to having just one headlamp and brakes on only one axle.

The American Revelation

In 1950, everything changed when Eiji Toyoda and veteran machinist Taiichi Ohno visited Ford’s River Rouge plant in Michigan. While impressed by the massive scale of American manufacturing, they quickly realized that Japan’s economic reality wouldn’t allow for such resource-intensive operations. Having months of inventory sitting in warehouses would tie up precious capital they simply didn’t have.

The Supermarket Inspiration

But it wasn’t Ford that provided the breakthrough insight—it was a Piggly Wiggly supermarket. At a time when Japan didn’t have self-service stores, Ohno was struck by how customers could choose exactly what they wanted, when they wanted it. This simple observation would become the foundation of Toyota’s revolutionary “Just-in-Time” production system.

Birth of the Toyota Production System

Between 1948 and 1975, Toyota developed what became known as the Toyota Production System (TPS), built on two fundamental pillars:

- Just-in-Time Production: Only producing what was needed, when it was needed

- Jidoka: Automation with a human touch

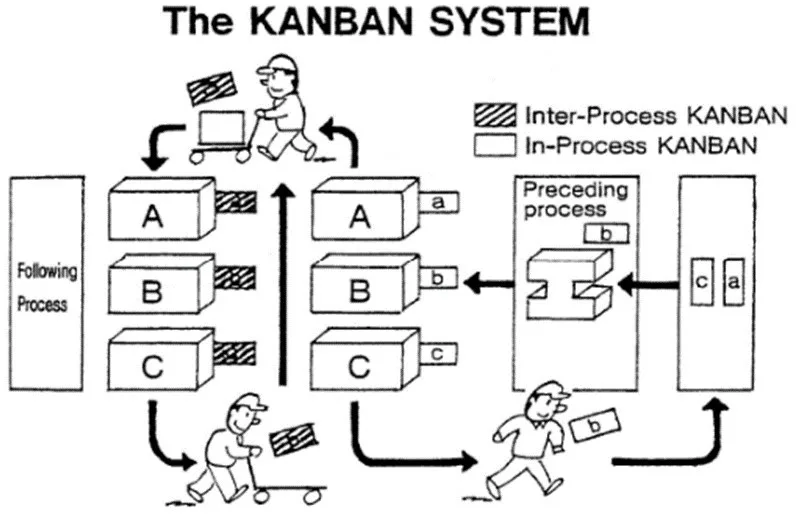

They implemented the Kanban system—a visual scheduling method showing goods in production and goods out—which would later be recognized as a precursor to modern barcodes.

Revolutionary Problem-Solving

While American manufacturers were still following Henry Ford’s principle of keeping operations at full tilt, Toyota took a radically different approach. They installed a chord at every station that any worker could pull to stop the entire assembly line if they spotted a problem. The whole team would then work together to prevent the issue from recurring.

This approach, combined with their culture of Kaizen (continuous incremental improvement), led to dramatic results. By 1962, Toyota had produced 1 million vehicles. By 1972, they’d reached 10 million. Their efficiency became so legendary that they could produce a car every 1.6 man-hours—far faster than competitors in the U.S., Sweden, and Germany.

The Global Impact

Today, Toyota has produced over 250 million vehicles, but their influence extends far beyond automotive manufacturing. Their system has been adopted by:

- Boeing: Restructured entire plants based on TPS principles

- Intel: Applying lean principles to AI and IoT development

- Healthcare: Canadian hospitals using Toyota’s system to decrease ER wait times

The Universal Lesson

Toyota’s story teaches us something profound about business and innovation: constraints aren’t obstacles—they’re catalysts for creativity. When you can’t throw money at problems, you’re forced to think differently. The company that once had to make trucks with single headlamps is now the global standard for manufacturing efficiency.

In the end, Toyota didn’t just change how cars are made—they changed how we approach making things from start to finish. Their story proves that there’s always a better way to make a product, and sometimes the best innovations come not from having more resources, but from learning to do more with less.

Today, as businesses face new constraints and challenges, Toyota’s lesson remains as relevant as ever: true innovation often comes not from abundance, but from necessity. Their journey from post-war struggle to global leadership continues to inspire companies worldwide to find opportunity in their limitations.